Welding

About The Program

Ever been fascinated by the idea of joining metal? Interested in having a good-paying, portable, practical skill? Learning to weld can open many career doors, or add to a Trade you already have, thereby making you that much more valuable as an employee.

Welders permanently join pieces of metal by applying heat, using filler metal or fusion process. They join parts being manufactured, build structures and repair damaged or worn parts. They also fabricate parts, tools, machines and uses a wide variety of occupational knowledge, skills and abilities in combination with cutting, gouging and welding processes to tack and weld assemblies and fabrications within a quality control system.

The welder’s work is usually, but not exclusively, found in industrial and commercial sectors such as assembly plants, factories, shipbuilding, refineries and building construction. Welders may work on the same site for prolonged periods and may routinely perform a variety of tasks including vehicle and implement repairs or construction, oilfield fabrication and repairs and heavy equipment servicing and maintenance. They may also specialize in areas such as underwater welding and welding of non-metal materials.

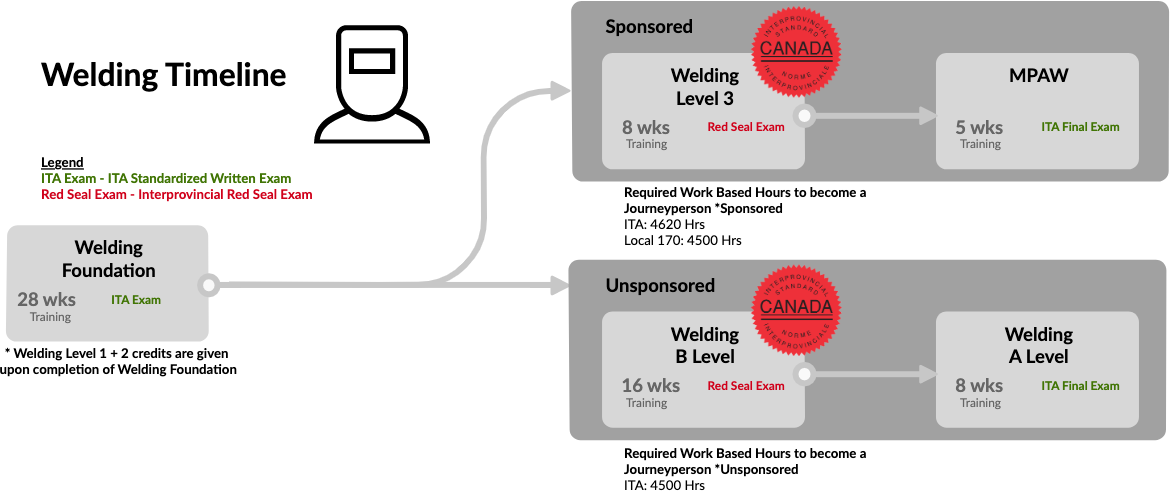

The program will be delivered in a variety of formats combining in school and work-based training, all designed to meet the competency standards and profile as defined by the industry. With the end result obtaining a Red-Seal and starting a career in welding.

Program Information:

Campus

- Delta

- Fort St. John

Certifications:

- Red Seal Certification

3 years

Information:

Equivalent to Welding Level 1 + 2

Training consists of learning the basics of the welding trade with an emphasis on safety. Note: Level 2 is included into the Level 1 program for Welding

This program has been approved by the Private Training Institutions Branch (PTIB) of the Ministry of Advanced Education, Skills & Training.

- Cutting, soldering and brazing

- Drafting and blueprint reading

- Hand and power tools

- Oxy-fuel cutting

- Introduction to Plumbing, Steamfitting, & Sprinkler Fitting

Program Outline: Welding Foundations Program Outline

Books:

- CWB Textbooks (Included in Tuition)

Exposure to intermediate technical aspects of the trade. Drafting and systems process is a strong focus, in addition to many practical shop projects.

This program has been approved by the Private Training Institutions Branch (PTIB) of the Ministry of Advanced Education, Skills & Training.

- Semi-automatic and Automatic Welding

- Gas Tungsten Arc Welding (GTAW)

- Welding Drawings, Layout and Fabrication

- Shielded Metal Arc Welding (SMAW)

- Basic Metallurgy

Program outline: Welder B Program Outline

Program Costs:

- Registration Fee – $100

- Tuition – $2,550

Books:

- CWB Textbooks (Included in Tuition)

Multi-Process Alloy Welding (MPAW) Certification. This level of technical training gives a welder to weld all materials including specialized alloys, by any manual process in any position.

This program does not require approval by the Private Training Institutions Branch (PTIB) of the Ministry of Advanced Education, Skills & Training. As such, PTIB did not review this program.

- Semi-automatic and Automatic Welding

- Gas Tungsten Arc Welding (GTAW)

- Welding Drawings, Layout and Fabrication

- Shielded Metal Arc Welding (SMAW)

- Specialized Processes

Program outline: Welding Level A Program Outline

Program Costs:

- Registration Fee – $100

- Tuition – $1,300

Pre-Requisites:

-

- Recommended education is Grade 12 or GED

- Minimum requirement is Grade 10 completion, including English, Math and Science 10

More Information:

Course Dates:

| Please see Schedule on Pre-Apprenticeship Page |

B-Level Class (16 weeks) September 19th, 2022 7am-2pm

A-Level Class (8 weeks) starting date : September 19th, 2022 (7am-2pm)